New project

WELCOME to High Plains Muzzle Loading Forum! :: Muzzleloading, Firearms & Optics :: Custom Gunsmithing & Builds

Page 1 of 1

New project

New project

Hey all,

First I will say I am not a gunsmith, I am a hobbyist. I have done a bunch of reading and this is my first attempt at this kinda work.

I picked up a Traditions Buck Hunter inline from a friend at work for 50 bucks. It hasn't been shot and was just sitting around. I have read that some say its not very consistent when shooting. So, I figured why not pick grab it and see what I can do to make it better, since I do like to tinker with stuff. When I was going over looking at it I noticed that the muzzle didn't look to be square, so I pulled the barrel and got it mounted in the lathe at work. Well, I can tell you that it wasn't even close to being square. I had to remove right a .070 to get it square. Once I did that I figured why not put a nice crown on it. I went for a "Step" style target crown. The inside bevel on the bore itself is 60 degrees with the inside edge being a 45 degree and the outside of the barrel being another 45 degrees as well. I went this direction, so it would make loading a patch ball easier if I decided to use one. Here are some pictures of what has be done so far. I will post more if you would like to see the progress. I have a show next week and will be gone, but after that I will post again.

First I will say I am not a gunsmith, I am a hobbyist. I have done a bunch of reading and this is my first attempt at this kinda work.

I picked up a Traditions Buck Hunter inline from a friend at work for 50 bucks. It hasn't been shot and was just sitting around. I have read that some say its not very consistent when shooting. So, I figured why not pick grab it and see what I can do to make it better, since I do like to tinker with stuff. When I was going over looking at it I noticed that the muzzle didn't look to be square, so I pulled the barrel and got it mounted in the lathe at work. Well, I can tell you that it wasn't even close to being square. I had to remove right a .070 to get it square. Once I did that I figured why not put a nice crown on it. I went for a "Step" style target crown. The inside bevel on the bore itself is 60 degrees with the inside edge being a 45 degree and the outside of the barrel being another 45 degrees as well. I went this direction, so it would make loading a patch ball easier if I decided to use one. Here are some pictures of what has be done so far. I will post more if you would like to see the progress. I have a show next week and will be gone, but after that I will post again.

Roblynch- Posts : 58

Join date : 2022-01-21

Age : 51

Location : Florida

188mule likes this post

Roblynch- Posts : 58

Join date : 2022-01-21

Age : 51

Location : Florida

188mule likes this post

Re: New project

Re: New project

Roblynch wrote:Hey all,

First I will say I am not a gunsmith, I am a hobbyist. I have done a bunch of reading and this is my first attempt at this kinda work.

I picked up a Traditions Buck Hunter inline from a friend at work for 50 bucks. It hasn't been shot and was just sitting around. I have read that some say its not very consistent when shooting. So, I figured why not pick grab it and see what I can do to make it better, since I do like to tinker with stuff. When I was going over looking at it I noticed that the muzzle didn't look to be square, so I pulled the barrel and got it mounted in the lathe at work. Well, I can tell you that it wasn't even close to being square. I had to remove right a .070 to get it square. Once I did that I figured why not put a nice crown on it. I went for a "Step" style target crown. The inside bevel on the bore itself is 60 degrees with the inside edge being a 45 degree and the outside of the barrel being another 45 degrees as well. I went this direction, so it would make loading a patch ball easier if I decided to use one. Here are some pictures of what has be done so far. I will post more if you would like to see the progress. I have a show next week and will be gone, but after that I will post again.

Rob you hit it right on. There is usually only 2 reasons a firearm isn't accurate: the barrel, or the operator.

There was a fellow that had all kinds of trouble getting accuracy from his muzzleloader. Someone told him to bend the barrel because sometimes the manufacturer produces a bent barrel.

Can you imagine that piece of advice?! If the manufacturer lets a bent barrel go out the door, they have one helluva liability coming their way! If you suspect a barrel problem, send it to a professional gunsmith and have it checked.

Guest- Guest

Re: New project

Re: New project

I'm thinking you are going to have a good shooter their. Nice pics.

It is definitely nice to have access to a lathe. Nice job.

It is definitely nice to have access to a lathe. Nice job.

Guest- Guest

Re: New project

Re: New project

Thank you Mustang65,

I am excited to get more done on this project. I am trying to decide now if I leave the plastic stock that it came with, or try adapting it to a wood stock and doing my own inlet work to fit it.

Wow bend your barrel to make it shoot better, that doesn't sound like something I would try to do let alone tell someone else to do it.

Can't wait to shoot it to see how it does. Just got home from shooting my Renegade that I put together from parts. What an accurate shooter so far.

Rob

I am excited to get more done on this project. I am trying to decide now if I leave the plastic stock that it came with, or try adapting it to a wood stock and doing my own inlet work to fit it.

Wow bend your barrel to make it shoot better, that doesn't sound like something I would try to do let alone tell someone else to do it.

Can't wait to shoot it to see how it does. Just got home from shooting my Renegade that I put together from parts. What an accurate shooter so far.

Rob

Roblynch- Posts : 58

Join date : 2022-01-21

Age : 51

Location : Florida

Re: New project

Re: New project

When you do get around to shooting it. Make sure you post some results.Roblynch wrote:Thank you Mustang65,

I am excited to get more done on this project. I am trying to decide now if I leave the plastic stock that it came with, or try adapting it to a wood stock and doing my own inlet work to fit it.

Wow bend your barrel to make it shoot better, that doesn't sound like something I would try to do let alone tell someone else to do it.

Can't wait to shoot it to see how it does. Just got home from shooting my Renegade that I put together from parts. What an accurate shooter so far.

Rob

Interesting to see if many of those barrels weren't square.

You know, you could fancy up that stock by doing a nice camo job on it.

If you decide to sell, should bring bigger bucks and I don't mean the horny type.( I should probably rephrase that..LOL)

Guest- Guest

Re: New project

Re: New project

I absolutely will post as I go through it. I thought about re painting the stock. I will re paint barrel assembly as it is now, so can easily do it at the same. Its got a fast twist barrel on it, so I think I will look at some new bullet options as well.

Rob

Rob

Roblynch- Posts : 58

Join date : 2022-01-21

Age : 51

Location : Florida

Re: New project

Re: New project

Good morning,

Well our first trade show of the year is over and had some time to get a little done. I didn't like the stock the way it came, so I decided to fill the stock with Epoxycast 655 and flock.

Once I scuffed the inside of the stock and drilled flow holes through the bulkheads I damed off the front with clay to help hold the filler in place.

The barrel uses 2 mounting points one in the front and one in the back. The front support I placed tape around to give it a little room for the bedding compound on the next step. Once I poured the filler I waited 4 hours for it to cure before proceeding to the next step.

Next I sprayed the barrel and all mating pieces with mold release. I used 3 coats to be sure it would not become permanent to the stock. I mixed up my bedding compound and filled in the area and pushed the barrel into place while tightened the retaining bolts slowly watching for the squeeze out. After sitting all night to cure I removed the bolts and using a rubber mallet gave it a good sharp crack and everything came apart as it should. It came out pretty good, its not my best bedding job, but it will work.The total additional weight was 1 pound. This is a bench gun and will be shot from a bag or a bipod.

Well our first trade show of the year is over and had some time to get a little done. I didn't like the stock the way it came, so I decided to fill the stock with Epoxycast 655 and flock.

Once I scuffed the inside of the stock and drilled flow holes through the bulkheads I damed off the front with clay to help hold the filler in place.

The barrel uses 2 mounting points one in the front and one in the back. The front support I placed tape around to give it a little room for the bedding compound on the next step. Once I poured the filler I waited 4 hours for it to cure before proceeding to the next step.

Next I sprayed the barrel and all mating pieces with mold release. I used 3 coats to be sure it would not become permanent to the stock. I mixed up my bedding compound and filled in the area and pushed the barrel into place while tightened the retaining bolts slowly watching for the squeeze out. After sitting all night to cure I removed the bolts and using a rubber mallet gave it a good sharp crack and everything came apart as it should. It came out pretty good, its not my best bedding job, but it will work.The total additional weight was 1 pound. This is a bench gun and will be shot from a bag or a bipod.

Last edited by Roblynch on 20/03/22, 10:35 am; edited 3 times in total

Roblynch- Posts : 58

Join date : 2022-01-21

Age : 51

Location : Florida

Roblynch- Posts : 58

Join date : 2022-01-21

Age : 51

Location : Florida

HC likes this post

Re: New project

Re: New project

Well I was able to get mostly done yesterday. Just need to reassemble and mount my optic. I hope to shoot it next weekend. Barrel parts are finished in Cerakote sniper gray and the stock was done with Alcohol Ink and Cerakote matte clear.

Roblynch- Posts : 58

Join date : 2022-01-21

Age : 51

Location : Florida

Roblynch- Posts : 58

Join date : 2022-01-21

Age : 51

Location : Florida

HC likes this post

Re: New project

Re: New project

Well not every range visit is a smooth one. Had some issues yesterday and learned a few things. I knew before I went to the range that I did not care for the trigger. I contacted Traditions about how to adjust it and they said it wasn't adjustable. It was breaking at 7lbs, but figured I would give it a go anyway and see how it did. Well it didn't is the easiest way I can say it. So, after 5 shots I was over it. I didn't feel a single shot was valid.

Once I returned home I decide to clean everything up and take a look at the trigger to see if I could improve it in any way. That was when the second problem came up, this one was self caused. I will get to that in a minute.

On the trigger and after marking all the factory settings I decided to make some adjustments to the rear screw. Well this did it, I was able to get the squeeze down from 7 lbs to 3 lbs consistently. After adjusting it I tried to get it to false fire on its own which I was not able to do.

On removal of the front barrel retaining bolt which is the " sling stud" I felt the barrel rise up in the stock with the back still being secured in the stock. Some where in my bedding process I was off causing the barrel to have tension when being tightened into the stock. I don't mean a small amount either. I will address this as its an easy fix. I hope next weekend will go a bit smoother and hope to report back with better results, as for the groups I was getting vertical dispersion around 3 inches, left to right was spot on. I am pretty sure the vertical was caused by the trigger being to hard for me to squeeze, or the barrel having tension on it. If anyone else has any thought on this please feel free to chime in here.

Thanks and have a great day.

Rob

Once I returned home I decide to clean everything up and take a look at the trigger to see if I could improve it in any way. That was when the second problem came up, this one was self caused. I will get to that in a minute.

On the trigger and after marking all the factory settings I decided to make some adjustments to the rear screw. Well this did it, I was able to get the squeeze down from 7 lbs to 3 lbs consistently. After adjusting it I tried to get it to false fire on its own which I was not able to do.

On removal of the front barrel retaining bolt which is the " sling stud" I felt the barrel rise up in the stock with the back still being secured in the stock. Some where in my bedding process I was off causing the barrel to have tension when being tightened into the stock. I don't mean a small amount either. I will address this as its an easy fix. I hope next weekend will go a bit smoother and hope to report back with better results, as for the groups I was getting vertical dispersion around 3 inches, left to right was spot on. I am pretty sure the vertical was caused by the trigger being to hard for me to squeeze, or the barrel having tension on it. If anyone else has any thought on this please feel free to chime in here.

Thanks and have a great day.

Rob

Roblynch- Posts : 58

Join date : 2022-01-21

Age : 51

Location : Florida

Re: New project

Re: New project

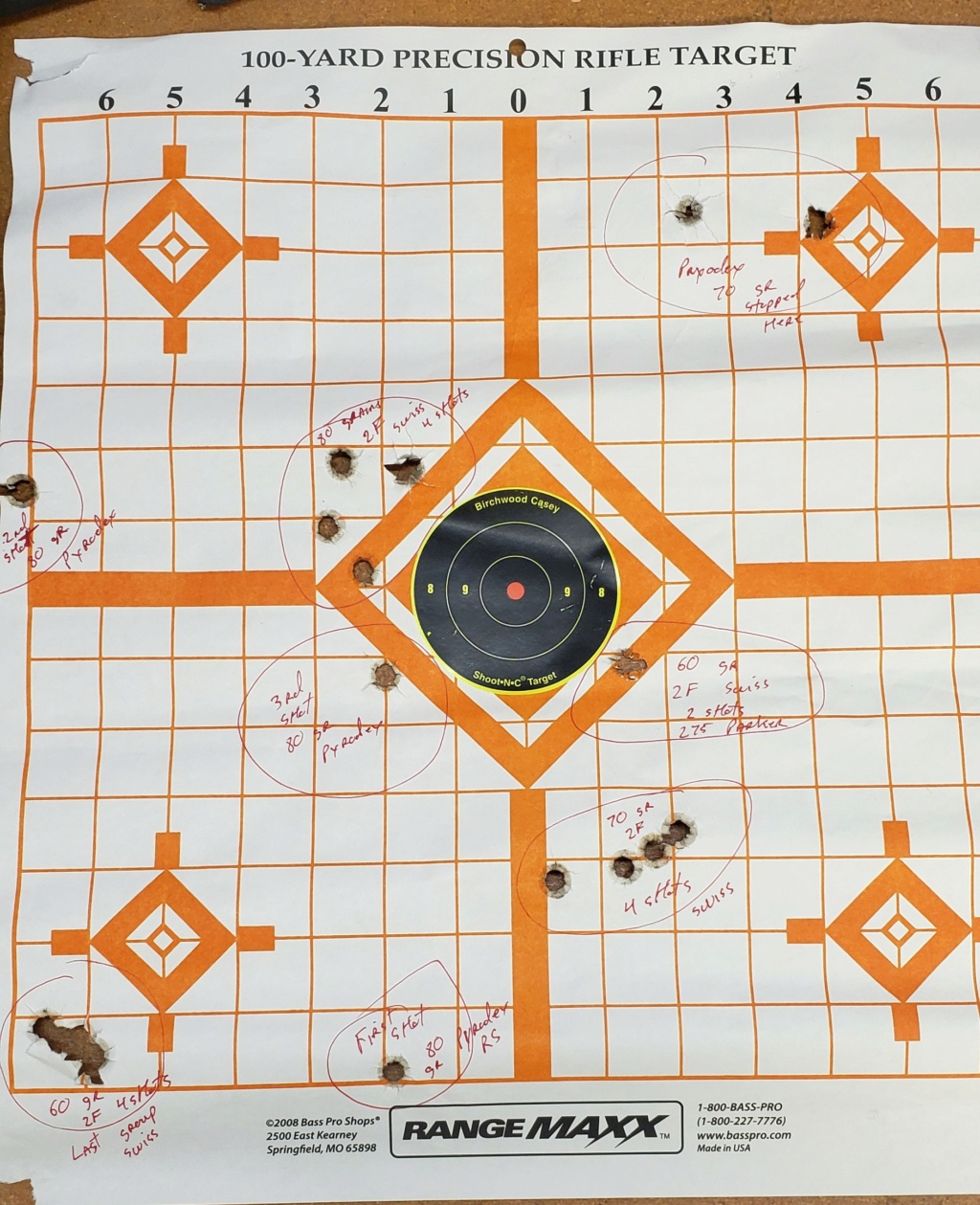

Had my second range visit this morning and it went much better. I corrected my issues with bedding and the trigger. This is all at 75 yards.

I wanted to try some Pyrodex that I had, so I started with that. It didn't really care for it and after shooting a few loads gave up and went back to Swiss 2f. It was a rocky start with that as well and thought maybe it was just going to be what it was.

I remember talking to Lewis about the accuracy range that he has noticed and backed off on my charge. That was a game changer for this setup at least with this bullet. I used my Accurate Molds 50-275B which I casted from 20-1. I did shoot another bullet as well, but stopped after the 2nd one to save them for a longer range session.

Here is my target with all the shots and they are labeled as to what they are. It seems my go to load will be 60 gr of 2F swiss by weight for now. I am looking at another mold for heavier bullet for this faster twist barrel.

I wanted to try some Pyrodex that I had, so I started with that. It didn't really care for it and after shooting a few loads gave up and went back to Swiss 2f. It was a rocky start with that as well and thought maybe it was just going to be what it was.

I remember talking to Lewis about the accuracy range that he has noticed and backed off on my charge. That was a game changer for this setup at least with this bullet. I used my Accurate Molds 50-275B which I casted from 20-1. I did shoot another bullet as well, but stopped after the 2nd one to save them for a longer range session.

Here is my target with all the shots and they are labeled as to what they are. It seems my go to load will be 60 gr of 2F swiss by weight for now. I am looking at another mold for heavier bullet for this faster twist barrel.

Last edited by Roblynch on 02/04/22, 02:12 pm; edited 1 time in total

Roblynch- Posts : 58

Join date : 2022-01-21

Age : 51

Location : Florida

Similar topics

Similar topics» Project Old Army?

» Hunting video project - Washington

» Seeking a grant writer for film project (muzzleloading)

» Hunting video project - Washington

» Seeking a grant writer for film project (muzzleloading)

WELCOME to High Plains Muzzle Loading Forum! :: Muzzleloading, Firearms & Optics :: Custom Gunsmithing & Builds

Page 1 of 1

Permissions in this forum:

You cannot reply to topics in this forum|

|

|