lyman GPR alligator teeth for rifling

+7

George_Kelley

Kurt

Buckskins&BlackPowder

Admin

188mule

HC

EasternOregon .50cal GPR

11 posters

WELCOME to High Plains Muzzle Loading Forum! :: Muzzleloading, Firearms & Optics :: Traditional Muzzle Loading

Page 3 of 3

Page 3 of 3 •  1, 2, 3

1, 2, 3

Re: lyman GPR alligator teeth for rifling

Re: lyman GPR alligator teeth for rifling

Looks like you got things worked out. Its amazing what a change in lube will do. My .58s like a patch with olive oil. And If I get lost and hungry I can eat them. Heck, they're only cotton and olive oil!

Whoa hold on. I didn't notice there were more pages on this thread. I agree with Lewis (as usual) You should be using pure lead and not wheel weights for your round balls. WWs are just too hard. I hope you tried that. I'm going to the last page now to see...

Whoa hold on. I didn't notice there were more pages on this thread. I agree with Lewis (as usual) You should be using pure lead and not wheel weights for your round balls. WWs are just too hard. I hope you tried that. I'm going to the last page now to see...

Bronko22000- Posts : 373

Join date : 2022-01-20

Age : 70

Location : Locust Gap, PA

Re: lyman GPR alligator teeth for rifling

Re: lyman GPR alligator teeth for rifling

FWIW.

Logic tells me that your main area of concern with any cutting of the patches should be in the contact area between the ball and the rifling. On a .50 cal ball that should be about 3/4” in diameter. The material outside of that diameter is not in compression between the ball and the rifling and further more has nothing to hold the fibres in place as the patch leaves the barrel at 1200 fps. My belief is that depending on the quality of the weave you will experience differing fraying around the OD of the patch. If you are not experiencing small cut holes thru the patch material in the contact diameter you are looking in the wrong area. The lead hardness, depth of rifling, type and quantity of lube all have significant effect on your precision. Ball too hard and the patch won’t grip the ball. Patch too loose and it won’t grip either ball or rifling creating blowby and not imparting any spin on the ball. Too much lube or not enough lube will have an effect also. I would suggest that you read Dutch Schoultz’s book on Black Powder Accuracy for a detailed explanation.

Smoke

Logic tells me that your main area of concern with any cutting of the patches should be in the contact area between the ball and the rifling. On a .50 cal ball that should be about 3/4” in diameter. The material outside of that diameter is not in compression between the ball and the rifling and further more has nothing to hold the fibres in place as the patch leaves the barrel at 1200 fps. My belief is that depending on the quality of the weave you will experience differing fraying around the OD of the patch. If you are not experiencing small cut holes thru the patch material in the contact diameter you are looking in the wrong area. The lead hardness, depth of rifling, type and quantity of lube all have significant effect on your precision. Ball too hard and the patch won’t grip the ball. Patch too loose and it won’t grip either ball or rifling creating blowby and not imparting any spin on the ball. Too much lube or not enough lube will have an effect also. I would suggest that you read Dutch Schoultz’s book on Black Powder Accuracy for a detailed explanation.

Smoke

LR_Smoker- Posts : 8

Join date : 2022-01-15

Location : Quebec, Canada

Ivan Wagurak, 188mule and EasternOregon .50cal GPR like this post

Re: lyman GPR alligator teeth for rifling

Re: lyman GPR alligator teeth for rifling

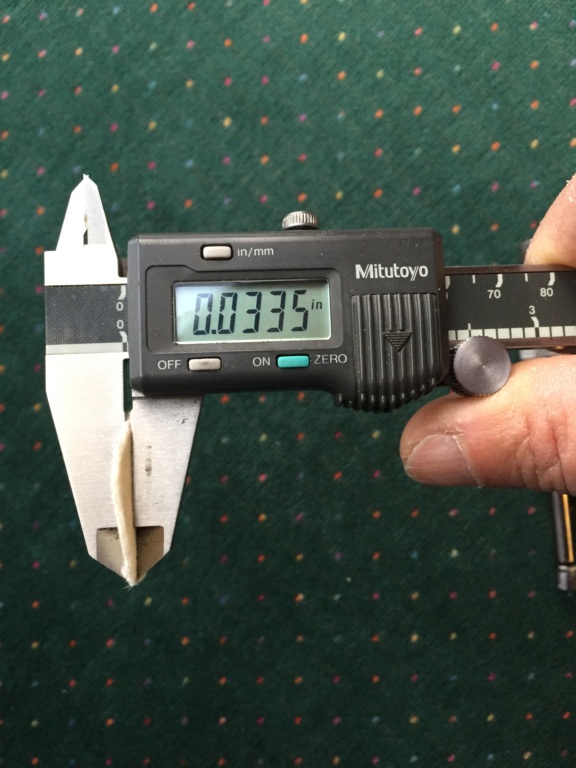

FWIW.

I have found that the most accurate way to measure material thickness ( at a reasonable price ) is to use a 0 to 1” micrometer NOT a vernier. Using a micrometer you can grasp the barrel between your trigger finger and thumb and applying a REASONABLE pressure on the smooth in knurled portion torque the spindle until it slips between you finger and thumb. With practice you will get surprisingly repeatable accuracy. The patch is supposed to be squeezed between the ball and the rifling and this approximates that compression more effectively than a vernier. The compressed thickness is very important and if you are very diligent in your tests you will notice a difference of even .001 thousandth in the patch affects your groups.

Smoke

LR_Smoker- Posts : 8

Join date : 2022-01-15

Location : Quebec, Canada

Re: lyman GPR alligator teeth for rifling

Re: lyman GPR alligator teeth for rifling

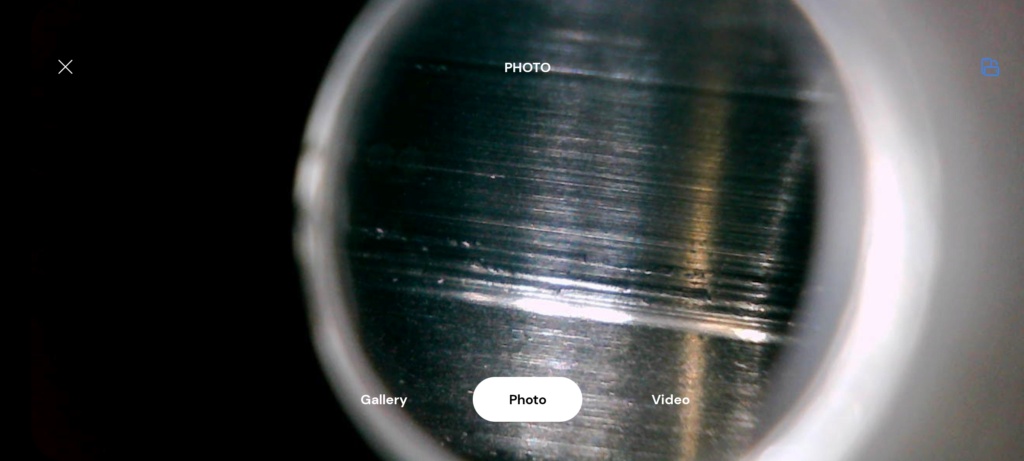

ok guys it's been awhile since I have gave an update on the lyman. I have barrel lapped the crapp out of it, I have spent hours lapping the barrel. A few minutes here and a few minutes there, when every I got an extra few minutes. followed by alot of time polishing with steel wool, ALOT of polishing, wondering if I am polishing a turd lol. again a few minutes here and few minutes there. I have been super busy farming but a am excited to get a chance to try it out again

I can't get the pictures to work at the moment or I would upload a picture of the barrel

I can't get the pictures to work at the moment or I would upload a picture of the barrel

EasternOregon .50cal GPR- Posts : 93

Join date : 2021-12-05

Age : 32

EasternOregon .50cal GPR- Posts : 93

Join date : 2021-12-05

Age : 32

Re: lyman GPR alligator teeth for rifling

Re: lyman GPR alligator teeth for rifling

You know I think you'll be fine. I don't think its so much the lines/scratches in the grooves that will hurt the accuracy as much as any burrs here and there in the bore. Something that will catch the patch and hold fouling. With what you did your patch should ride nicely in the rifling with the proper thickness and lube.

Bronko22000- Posts : 373

Join date : 2022-01-20

Age : 70

Location : Locust Gap, PA

Re: lyman GPR alligator teeth for rifling

Re: lyman GPR alligator teeth for rifling

LR While I agree that you can get accurate reading with a mic I also believe you can do it with calipers. I've spend my entire career using various measuring equipment and I have a pretty good "feel" using both. But those that haven't spent as much time as guys like me or machinists would do well to get themselves a mic. - either a 1/2" or 1"LR_Smoker wrote:

FWIW.

I have found that the most accurate way to measure material thickness ( at a reasonable price ) is to use a 0 to 1” micrometer NOT a vernier. Using a micrometer you can grasp the barrel between your trigger finger and thumb and applying a REASONABLE pressure on the smooth in knurled portion torque the spindle until it slips between you finger and thumb. With practice you will get surprisingly repeatable accuracy. The patch is supposed to be squeezed between the ball and the rifling and this approximates that compression more effectively than a vernier. The compressed thickness is very important and if you are very diligent in your tests you will notice a difference of even .001 thousandth in the patch affects your groups.

Smoke

Bronko22000- Posts : 373

Join date : 2022-01-20

Age : 70

Location : Locust Gap, PA

Re: lyman GPR alligator teeth for rifling

Re: lyman GPR alligator teeth for rifling

that's what I am hoping the steel wool eliminated anything that the patch could catch on. It really shined up the inside of the barrel when I did that

EasternOregon .50cal GPR- Posts : 93

Join date : 2021-12-05

Age : 32

Page 3 of 3 •  1, 2, 3

1, 2, 3

Similar topics

Similar topics» .54 cal. Lyman trade rifle

» .54 Cal Green Mountain LRH, Prep for upcoming Cow Elk Hunt

» lyman GPR trigger swap

» Lyman getting into shape and going on a diet

» Lyman GPR mule deer

» .54 Cal Green Mountain LRH, Prep for upcoming Cow Elk Hunt

» lyman GPR trigger swap

» Lyman getting into shape and going on a diet

» Lyman GPR mule deer

WELCOME to High Plains Muzzle Loading Forum! :: Muzzleloading, Firearms & Optics :: Traditional Muzzle Loading

Page 3 of 3

Permissions in this forum:

You cannot reply to topics in this forum